How To Use A Bearing Puller

Choosing the correct bearing puller for dismounting bearings is critical and selecting the correct puller is central to ensuring safe and easy removal.

In this article, we'll explicate the types of bearing pullers bachelor and how to decide which one is right for your application.

What is a bearing puller?

A bearing puller is a tool which is used to remove components such equally bearings, gears and pulleys from a shaft or a recess. The puller securely grips the component with specially designed jaws before driving it off the shaft.

A bearing puller is a tool which is used to remove components such equally bearings, gears and pulleys from a shaft or a recess. The puller securely grips the component with specially designed jaws before driving it off the shaft.

Pullers are used in every industry for safely and effectively dismounting bearings. Whether you're working in the automotive industry or the food and beverage manufacture, a bearing pulley could facilitate like shooting fish in a barrel dismounting of your bearings and other components.

Why employ a bearing puller?

Pullers are one of the most effective methods of cold dismounting. When a component is deeply mounted and cannot exist loosened manually, that'due south where a bearing pullers come in.

This could include situations where a damaged role has led to car breakdown. The failed component must exist removed as apace and every bit safely as possible in order to keep downtime to a minimum.

If you don't have whatsoever specialist tools around, it could be tempting to utilize a hammer and animal force to remove the bearing. Still, this tin pb to surrounding components condign damaged, causing further downtime.

A bearing puller can efficiently remove the stuck component from the shaft or recess, without causing whatever harm to the shaft or other surrounding components. This helps to promote the uptime and reliability of your machinery.

Begetting pullers too offering a safe method of removal when compared to techniques such as animal force or naked flames. Leading manufacturers such as SKF accept optimised puller design to ensure that they enable maximum worker safety. After all, no business wants to see their staff injured.

Bearing puller types

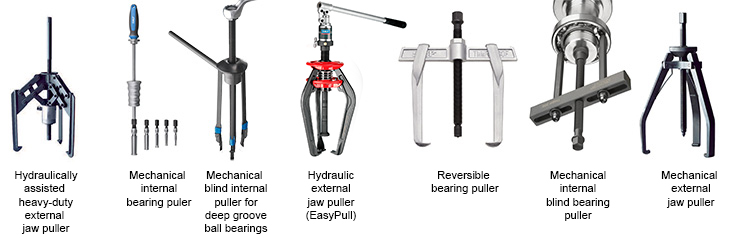

Every begetting puller falls into the broad categories of either an external bearing puller and an internal bearing puller.

External bearing pullers are used when the bearing is mounted onto a shaft. They have jaws which grip the outer diameter of the bearing, along with a forcing screw which pushes against the end of the shaft. As the forcing screw is tightened, the jaws forcefulness the bearing along the shaft.

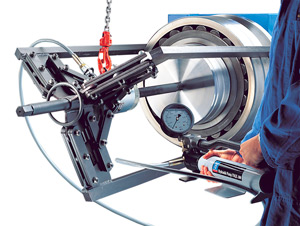

This type of puller can exist either mechanical or hydraulically-assisted. AHydraulic Bearing Puller requires minimal manual attempt, making them ideal for heavy-duty applications. Notwithstanding, specialist heavy-duty bearing pullers are as well available for these applications.

Internal or blind bearing pullers are used where the bearing or component is fitted within a recess, with an opening in the inner diameter. The puller is inserted into the inner diameter of the bearing where information technology grips the bearing. This can exist through expansion or using claws. The bearing can then be pulled from the recess.

Reversible bearing pullers are also available. This type of pullers is suitable for both internal and external pulling, thank you to their reversible artillery. This makes them ideal for use in applications where at that place are bearings fitted both on shafts and in recesses.

How to decide what type of puller to employ

The determination of which puller to apply is dependent on many factors. You'll first need to establish whether you need an external or an internal begetting puller.

If the component that yous're removing is seated on a shaft and is freely accessibly from the outer diameter, y'all'll need an external bearing puller. This is the nigh common blazon of puller. Withal, if the function you're trying to remove is in a recess with the inner diameter accessible, you'll need an internal begetting puller.

If y'all require an external bearing puller, you'll and then be able to choose between mechanical and hydraulic bearing pullers. If you're on a tight upkeep, a mechanical bearing puller may exist suitable. However, if you're working with heavy-duty machinery, y'all might consider a hydraulically-assisted bearing puller to reduce the transmission try required.

If y'all require an external bearing puller, you'll and then be able to choose between mechanical and hydraulic bearing pullers. If you're on a tight upkeep, a mechanical bearing puller may exist suitable. However, if you're working with heavy-duty machinery, y'all might consider a hydraulically-assisted bearing puller to reduce the transmission try required.

Y'all'll also need to consider the space conditions. This includes the diameter and depth of the begetting, along with the bachelor space around the bearing. Some bearing pullers volition require more space to operate than others.

The option of which bearing puller to employ should always be made subsequently conscientious consideration of all influencing factors. If you're unsure which begetting puller to cull, information technology'due south all-time to consult an skillful before making your conclusion.

Ownership a bearing puller

When y'all need a bearing puller on a short atomic number 82 time, it can be tempting to type 'purchase bearing puller online' into Google and click on the start option that appears. Nevertheless, you need to be certain that you're purchasing the correct bearing puller for your needs, likewise as a genuine and reliable tool.

At ACORN, we offer same day availability on our stocked range of pullers. Our authorised distributorship status means that many more options are available on a adjacent-twenty-four hours basis. And so whatever your requirements, we can source a genuine and reliable part apace.

If you need help, our squad are on manus to notice the right bearing puller for your application.

Source: https://www.acorn-ind.co.uk/insight/what-type-of-bearing-puller-should-i-use/

0 Response to "How To Use A Bearing Puller"

Post a Comment